The rubber industry is closely related to the auto-car industry. In other words, the auto car industry has advanced the development of the rubber products industry to a large extent. In addition to the car, the tire being visible to the naked eye, there are parts of automobile construction that are dependent on rubber production due to its excellent chemical properties and low price. With the continuous development of the auto car industry, people’s requirements for automobile performance are also gradually improving. It also requires rubber parts to play an increasingly powerful role in them. There are as many as 200 to 300 types of rubber fittings on the ordinary car. What is more, maybe 500 to 600 types of auto rubber parts on trucks and other models. The use of rubber production in automobiles can be roughly divided into the following three categories:

1, Car rubber pipe:

The car needs many tubular accessories. Such as air conditioning pipes, heat dissipation pipes, water tank pipes, gasoline pipes, and so on. The use of pipes in automobiles is extremely high in terms of characteristic requirements. And rubber has a natural temperature resistance, oil resistance, water resistance, wear resistance, etc. Especially it depends on the unique chemical stability of rubber when the vehicle is bumpy.

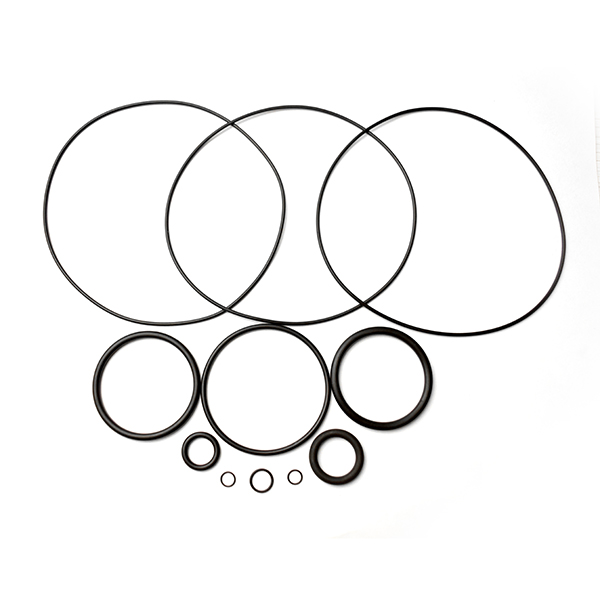

2, Car rubber seals:

Rubber seals are generally used as an isolate of liquid on the car. Rubber products have corrosion resistance, aging resistance, and temperature resistance. Therefore, they have great advantages as auto parts with long service life.

3, Car damping rubber parts:

Whether the car is in brake or in the situation of road potholes, the damping performance needs to come into play. Rubber buffer has good mechanical properties, which can be part of the pressure for the car to be cushioned.

In the future, rubber parts in the field of automotive performance will be larger and larger. The application would be more and more extensive. Engineers are constantly developing new applications for rubber products according to the needs of cars.