Rubber o rings are one of the most commonly used sealing solutions in various industries. They are versatile, cost-effective, and reliable. In this ultimate guide, we will explore everything you need to know about rubber o rings, including their properties, types, applications, and maintenance.

Properties of Rubber O Rings

Rubber o rings are made of elastomers, which are materials that can deform and return to their original shape when subjected to stress. The most common elastomers used in rubber o rings are nitrile rubber (NBR), silicone rubber (VMQ), fluorocarbon rubber (FKM), and ethylene propylene diene monomer (EPDM).

Each elastomer has its own unique properties that make it suitable for specific applications. For example, NBR is resistant to oil and fuel, while VMQ can withstand high temperatures. FKM is highly resistant to chemicals, and EPDM is ideal for outdoor applications due to its excellent weather resistance.

Types of Rubber O Rings

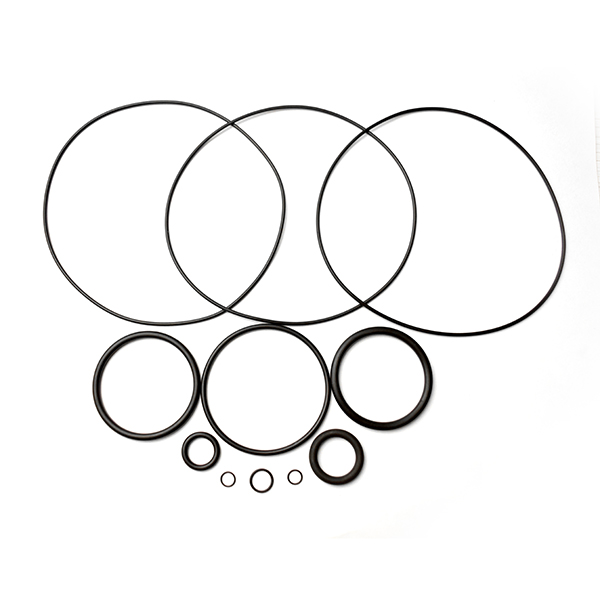

Rubber o rings come in various types, shapes, and sizes. The most common types are:

1. Standard o rings: These are the most basic type of rubber o rings and are available in a wide range of sizes and materials.

2. Quad rings: These are similar to standard o rings but have four sealing surfaces instead of two, providing better sealing performance.

3. X rings: These have a cross-sectional shape that resembles the letter X, providing better sealing performance than standard o rings.

4. D rings: These have a D-shaped cross-section and are commonly used in hydraulic applications.

5. Square rings: These have a square cross-section and are used in static sealing applications.

Applications of Rubber O Rings

Rubber o rings are used in various industries, including automotive, aerospace, oil and gas, food and beverage, and medical. Some common applications include:

1. Sealing hydraulic and pneumatic systems

2. Sealing pumps, valves, and fittings

3. Sealing engines and transmissions

4. Sealing food and beverage processing equipment

5. Sealing medical devices

Maintenance of Rubber O Rings

Proper maintenance is essential to ensure the longevity and performance of rubber o rings. Here are some tips for maintaining rubber o rings:

1. Store o rings in a cool, dry place away from direct sunlight and chemicals.

2. Inspect o rings regularly for signs of wear, cracking, or damage.

3. Replace o rings as soon as they show signs of wear or damage.

4. Use the correct lubricant for the specific elastomer used in the o ring.

5. Avoid using sharp tools or abrasive materials when handling o rings.

Conclusion

Rubber o rings are a versatile and reliable sealing solution that can be used in various industries and applications. Understanding their properties, types, applications, and maintenance is essential to ensure their optimal performance. By following the tips outlined in this guide, you can ensure the longevity and reliability of your rubber o rings.

Related Products